Sep. 02, 2025

7 minutes read

Share this article

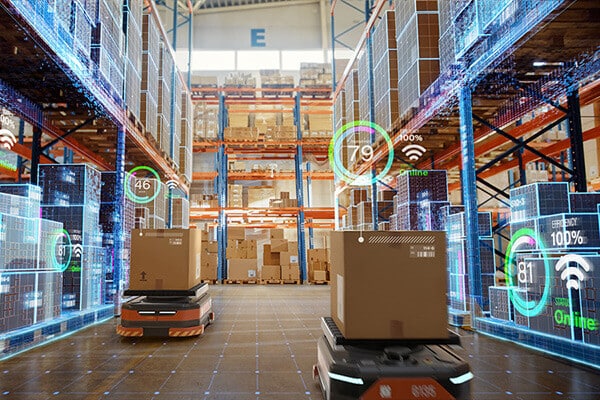

Autonomous robotics has emerged as a transformative force in the logistics industry, fundamentally changing how goods are stored, sorted, and delivered across global supply chains. The integration of artificial intelligence, advanced sensors, and robotic systems is enabling unprecedented levels of automation in warehouse operations and last-mile delivery, reducing operational costs while improving efficiency and accuracy. Companies worldwide are implementing autonomous robots for tasks ranging from inventory management to package sorting, marking a techtonic shift from traditional manual processes to intelligent automated systems.

The convergence of robotics technology with modern supply chain demands addresses critical challenges facing the logistics industry, including labor shortages, rising customer expectations for faster delivery, and the need for greater operational precision. Autonomous robots now navigate warehouse floors independently, optimize picking routes, and coordinate with human workers to streamline complex logistics operations. This technological evolution represents more than simple automation—it establishes new standards for how supply chains function in an increasingly connected world.

Understanding the core technologies driving this transformation and their impact on both logistics performance and workforce dynamics reveals the scope of change reshaping the industry. The adoption of autonomous robotics in logistics continues to accelerate as companies recognize the competitive advantages these systems provide in meeting modern supply chain requirements.

Autonomous robotics in logistics relies on sophisticated AI and machine learning systems that enable warehouse automation, transportation optimization, and last-mile delivery solutions. These technologies integrate with warehouse management systems to create comprehensive automation strategies across distribution centers.

AI algorithms form the foundation of autonomous logistics robots by enabling real-time decision-making and adaptive responses. Machine learning models process vast datasets from warehouse operations to optimize routing, inventory management, and task prioritization.

Computer vision systems allow robots to identify products, read barcodes, and navigate warehouse environments without human intervention. These systems integrate with warehouse management systems to maintain accurate inventory tracking and reduce manual workload.

Predictive analytics, powered by machine learning, helps anticipate demand patterns and optimize robot deployment across distribution centers. The technology enables autonomous mobile robots to learn from operational data and continuously improve performance metrics.

Natural language processing capabilities allow logistics robots to interpret voice commands and communicate with human workers. This integration creates collaborative environments where cobots work alongside warehouse staff efficiently.

Autonomous Guided Vehicles (AGVs) follow predetermined paths using magnetic strips, wires, or laser guidance systems. These industrial robots handle heavy payload transportation between warehouse zones and loading docks.

Autonomous Mobile Robots (AMRs) use dynamic navigation and obstacle avoidance to move freely throughout warehouses. AMRs adapt to changing environments and optimize routes in real-time, eliminating the need for infrastructure modifications.

| Robot Type | Primary Function | Navigation Method |

| AGVs | Heavy transport | Fixed pathways |

| AMRs | Flexible picking | Dynamic mapping |

| Sorting robots | Package sorting | Conveyor integration |

| Inventory drones | Stock counting | Aerial navigation |

Collaborative robots work directly with human employees in picking and packing operations. These cobots enhance productivity while maintaining safety protocols in shared workspace environments.

Swarm robotics coordinates multiple robots to handle large-scale warehouse operations simultaneously. The technology enables efficient task distribution and reduces bottlenecks in high-volume distribution centers.

Goods-to-person systems bring inventory directly to human workers using AMRs and conveyor belts. Amazon Robotics pioneered this approach with Kiva Systems, reducing walking time and increasing picking accuracy.

Autonomous delivery vehicles handle last-mile logistics using GPS navigation and obstacle avoidance technology. These vehicles reduce delivery costs and extend service hours beyond traditional driver schedules.

Delivery drones provide rapid transportation for lightweight packages in urban and remote areas. Battery life limitations currently restrict range, but advancing technology continues to extend operational capabilities.

Loading dock automation uses industrial robots to transfer packages between delivery trucks and warehouse systems. These robots reduce manual labor requirements and minimize package handling damage.

Route optimization algorithms powered by machine learning analyze traffic patterns, delivery windows, and customer preferences. The technology enables autonomous vehicles to select optimal paths and reduce fuel consumption.

Mobile robots equipped with temperature control systems handle specialized deliveries for pharmaceuticals and perishable goods. These autonomous systems maintain cold chain integrity throughout the delivery process.

Autonomous robotics transforms logistics operations through enhanced efficiency and reliability, while creating significant changes to the workforce. These technologies optimize supply chains through advanced route planning and demand forecasting, leading to new models of human-robot collaboration.

Autonomous robotics delivers measurable improvements in operational efficiency across warehouse and distribution operations. Robotic systems operate continuously without breaks, reducing processing times by 30-50% compared to manual operations.

These systems enhance reliability through consistent performance and reduced human error. Automated guided vehicles (AGVs) maintain precise navigation paths, while robotic picking systems achieve 99.9% accuracy rates in order fulfillment.

Key efficiency gains include:

Real-time data collection enables predictive maintenance, preventing equipment failures before they occur. This proactive approach maintains consistent operational uptime and reduces unexpected disruptions.

Autonomous systems revolutionize supply chains through advanced route optimization and demand forecasting capabilities. Machine learning algorithms analyze traffic patterns, weather conditions, and delivery constraints to determine optimal routes.

These systems reduce transportation costs by 15-25% through improved route planning. Autonomous vehicles coordinate deliveries to minimize fuel consumption and maximize vehicle utilization rates.

Demand forecasting becomes more accurate through continuous data analysis and refinement. Robotic systems track inventory levels in real-time, automatically triggering replenishment orders based on predictive models.

Edge computing enables instant decision-making at distribution centers, reducing delays in order processing and shipment preparation.

Human-robot collaboration creates new operational models where workers focus on complex decision-making while robots handle repetitive tasks. This partnership increases overall productivity by combining human creativity with robotic precision.

Job displacement affects routine positions, particularly in warehousing and sorting operations. However, new roles emerge in robot maintenance, system programming, and quality oversight.

Workers transition to supervisory positions that require technical skills and problem-solving abilities. Training programs help existing employees adapt to collaborative work environments with autonomous systems.

Workforce changes include:

Last-mile delivery operations particularly benefit from human-robot teams, where human drivers handle complex deliveries while robots manage standard routes.

The rise of autonomous robotics in logistics is not just about adopting new technology—it’s about redefining how supply chains operate in a world that demands speed, accuracy, and adaptability. By integrating AI-driven robotics into daily operations, companies are achieving unprecedented levels of efficiency while addressing labor shortages and reducing human error.

As these systems become more advanced, the benefits extend far beyond cost savings. Autonomous robotics enables real-time data collection, predictive analytics, and seamless coordination across the entire supply chain ecosystem. Businesses embracing this technology are setting new benchmarks for delivery speed, operational resilience, and customer satisfaction.

Ultimately, the shift toward autonomous robotics represents a long-term transformation rather than a passing trend. Companies that strategically implement these technologies today will be the ones leading tomorrow’s logistics landscape—faster, smarter, and ready to meet the challenges of a rapidly evolving global marketplace.

As the Vice President of Sales, Michael leads revenue growth initiatives in the US and LATAM markets. He focuses on three core pillars to drive success: fostering continuous improvement within our sales team and ensuring they consistently have the necessary skills and resources to exceed targets; creating and optimizing processes to maximize efficiency and effectiveness throughout the sales cycle; consolidating tools and technologies, streamlining our lead generation capabilities to improve our market reach and conversion rates.

As the Vice President of Sales, Michael leads revenue growth initiatives in the US and LATAM markets. He focuses on three core pillars to drive success: fostering continuous improvement within our sales team and ensuring they consistently have the necessary skills and resources to exceed targets; creating and optimizing processes to maximize efficiency and effectiveness throughout the sales cycle; consolidating tools and technologies, streamlining our lead generation capabilities to improve our market reach and conversion rates.

Accelerate your software development with our on-demand nearshore engineering teams.